14C28N is widely used in knives because it offers a well-balanced combination of edge performance, corrosion resistance, and maintainability. In practical knife design, this balance is often more valuable than single-metric optimization.

This guide explains what 14C28N means in knife performance, where it performs best, where its limits are, and how to maintain 14C28N knives for consistent service.

14C28N is a martensitic stainless chromium steel developed for knife applications where edge stability and corrosion resistance are primary requirements. The producer’s material positioning emphasizes suitability for professional knife use, including edge sharpness and resistance to corrosion.

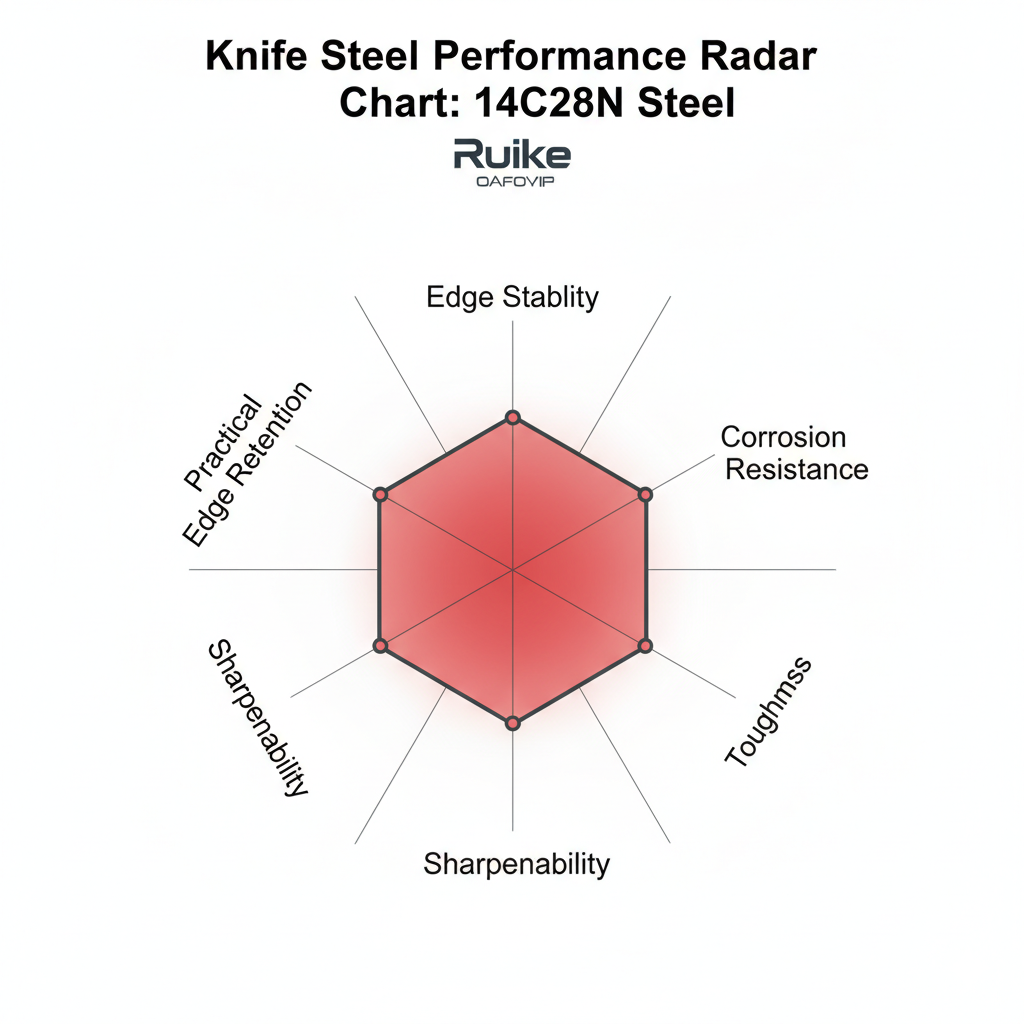

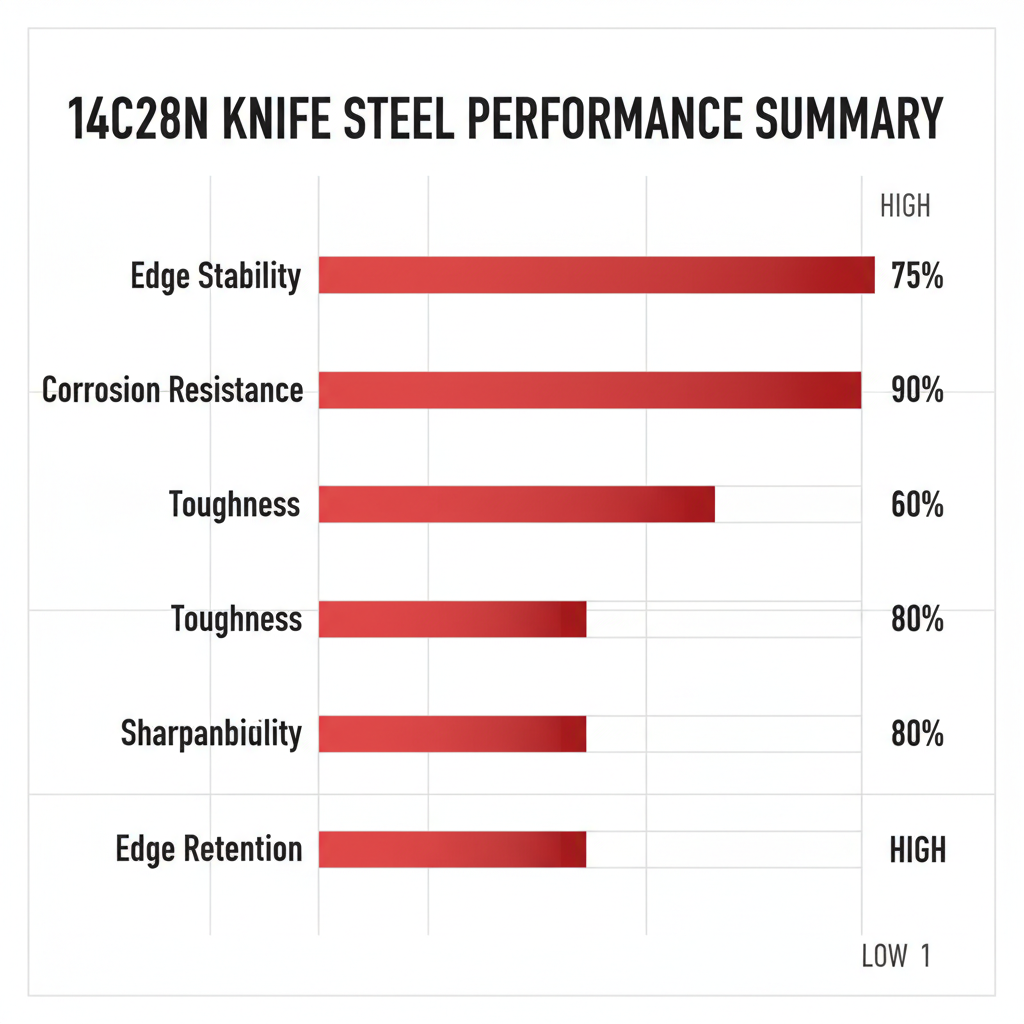

For knives, the main value of 14C28N is not extreme specialization, but predictable performance across multiple priorities:

Knife performance is strongly influenced by heat treatment and final edge geometry. Even within the same steel designation, hardness and edge behavior can vary by maker and process.

The official datasheet guidance indicates that deep freezing after hardening can increase hardness by approximately 1–2 HRC, and it also provides guidance on hardness adjustment through tempering parameters.

The practical implication is straightforward: evaluate a knife by its cutting performance and edge stability in use, not by steel name alone.

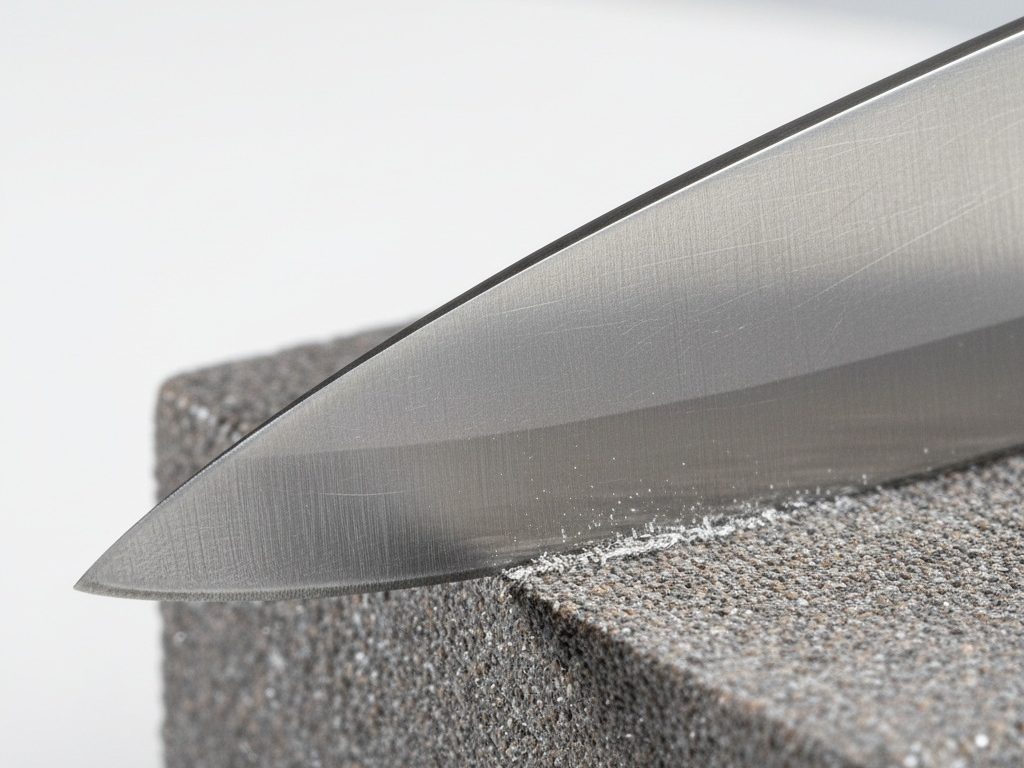

14C28N is commonly selected for knives that prioritize clean cutting and controlled edge behavior. In thin or slicey geometries, it supports a refined apex and stable edge line, which contributes to consistent cutting performance in everyday materials such as packaging, plastics, cordage, and food.

In knife terms, this is best described as edge stability: the edge can be made keen without becoming overly fragile under normal cutting loads.

14C28N is not designed to compete with high-wear, high-vanadium powder metallurgy steels in maximum abrasion resistance. Instead, its edge retention is typically characterized by:

From an engineering standpoint, this is a deliberate trade-off: 14C28N prioritizes balanced performance and maintainability rather than peak wear resistance.

Knife toughness is best evaluated at the edge: resistance to micro-chipping and edge instability during mixed cutting, minor lateral loading, and imperfect contact conditions.

14C28N is often valued because it can support thin edges with a lower tendency toward brittle micro-damage compared with some higher-wear stainless options, provided the knife is properly heat treated and ground. This makes it suitable for:

Corrosion resistance is a primary reason users select stainless steels for knives. 14C28N provides strong resistance to common environmental exposure, including humidity, sweat, and food acids, which reduces maintenance burden in daily use.

Stainless, however, does not mean maintenance-free. Proper drying after wet use and appropriate storage practices remain relevant for long-term condition stability.

A practical advantage of 14C28N is its approachable sharpening behavior. For most users, standard sharpening stones and a consistent technique are sufficient to restore performance without specialized abrasives.

This aligns with the design intent of 14C28N in knives: stable working sharpness with practical upkeep.

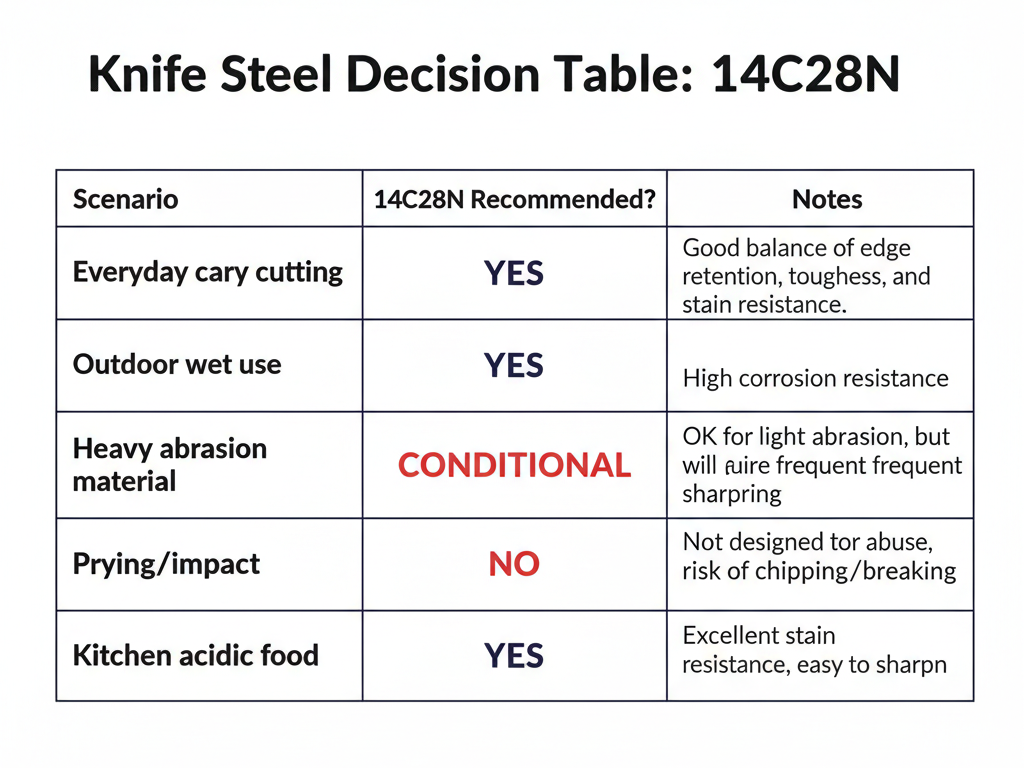

14C28N is a strong choice when the knife is expected to perform across daily or outdoor tasks with reasonable maintenance. Typical fit includes:

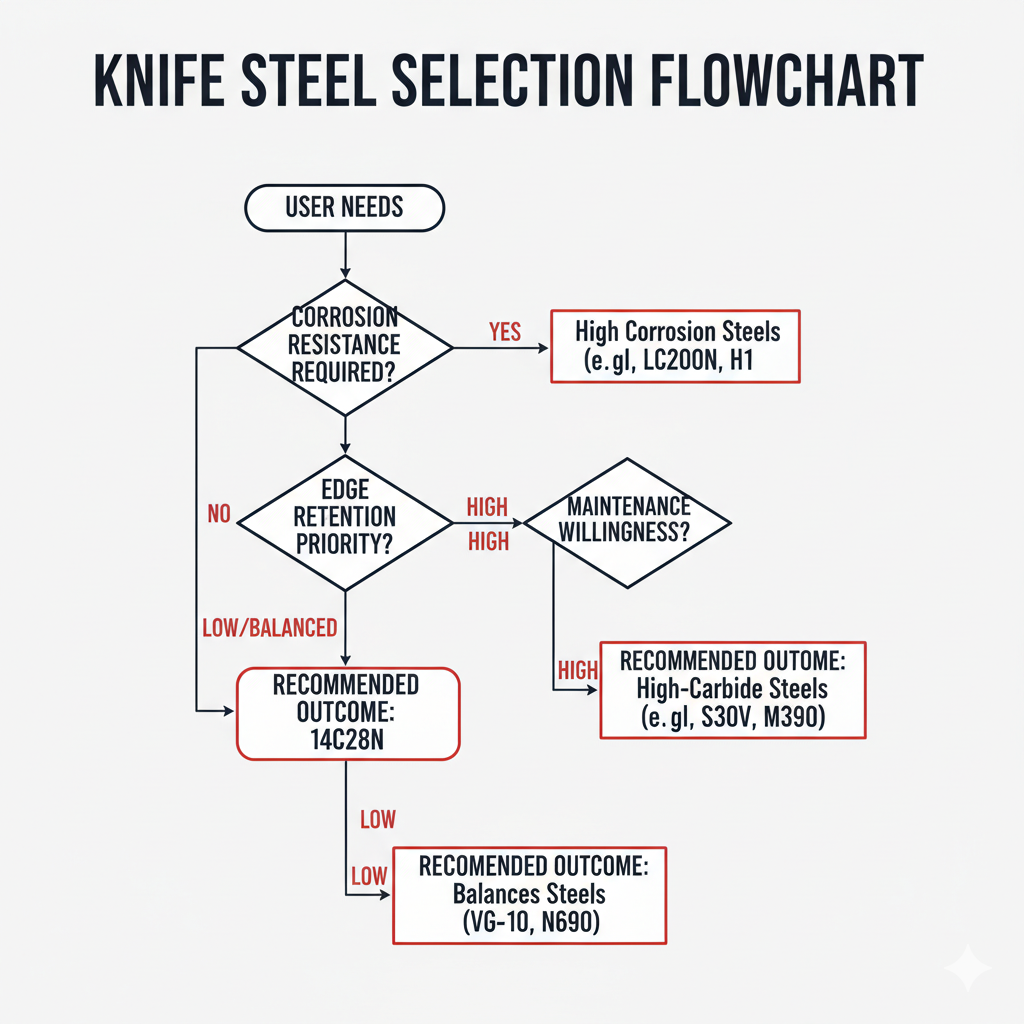

A different steel may be more appropriate when the use case is dominated by one extreme requirement:

These conditions favor steels optimized specifically for wear resistance or impact tolerance, often with different trade-offs in sharpening effort and corrosion behavior.

Performance depends on alloy design, heat treatment, geometry, and intended use. 14C28N is commonly chosen because its balance is appropriate for many knife applications.

Stainless steels resist corrosion but can still be affected by salt exposure, prolonged moisture, and improper storage.

Hardness can support edge retention, but excessive hardness in thin geometries can reduce edge stability and increase chipping risk.

For knives, edge stability, corrosion resistance, and maintenance practicality often determine overall service value.

In practical knife selection, 14C28N is typically positioned as:

The most useful comparison framework is application-driven: match steel and geometry to the cutting environment and maintenance expectations.

Yes. 14C28N is a strong knife steel when the goal is balanced performance: stable cutting edges, high corrosion resistance, and practical maintenance. Its value is most evident in everyday carry and outdoor utility knives where consistent service and ease of upkeep matter as much as maximum wear resistance.